XB-550i HD Bead Breaker for Tractor/OTR/Commercial/Industrial Tires

XB-550i HD Bead Breaker for Tractor/OTR/Commercial/Industrial Tires

Regular price

$33.79 USD

Regular price

$0.00 USD

Sale price

$33.79 USD

Unit price

per

Shipping calculated at checkout.

❤️🔥 1500+ orders shipped last month

🚚 Fast Delivery

🔒 Safe and Secured Checkout

Note: Only 8 left in stock

Couldn't load pickup availability

About this item

- ALL NEW DESIGN UPDATE - 11/2024 - major improvements over old design.

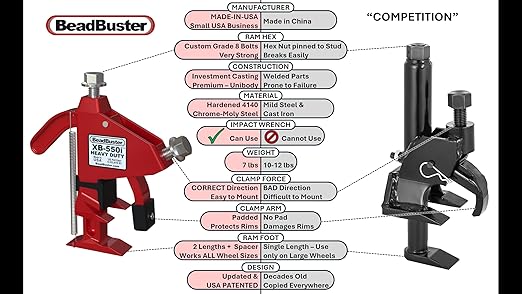

- MADE-IN-USA

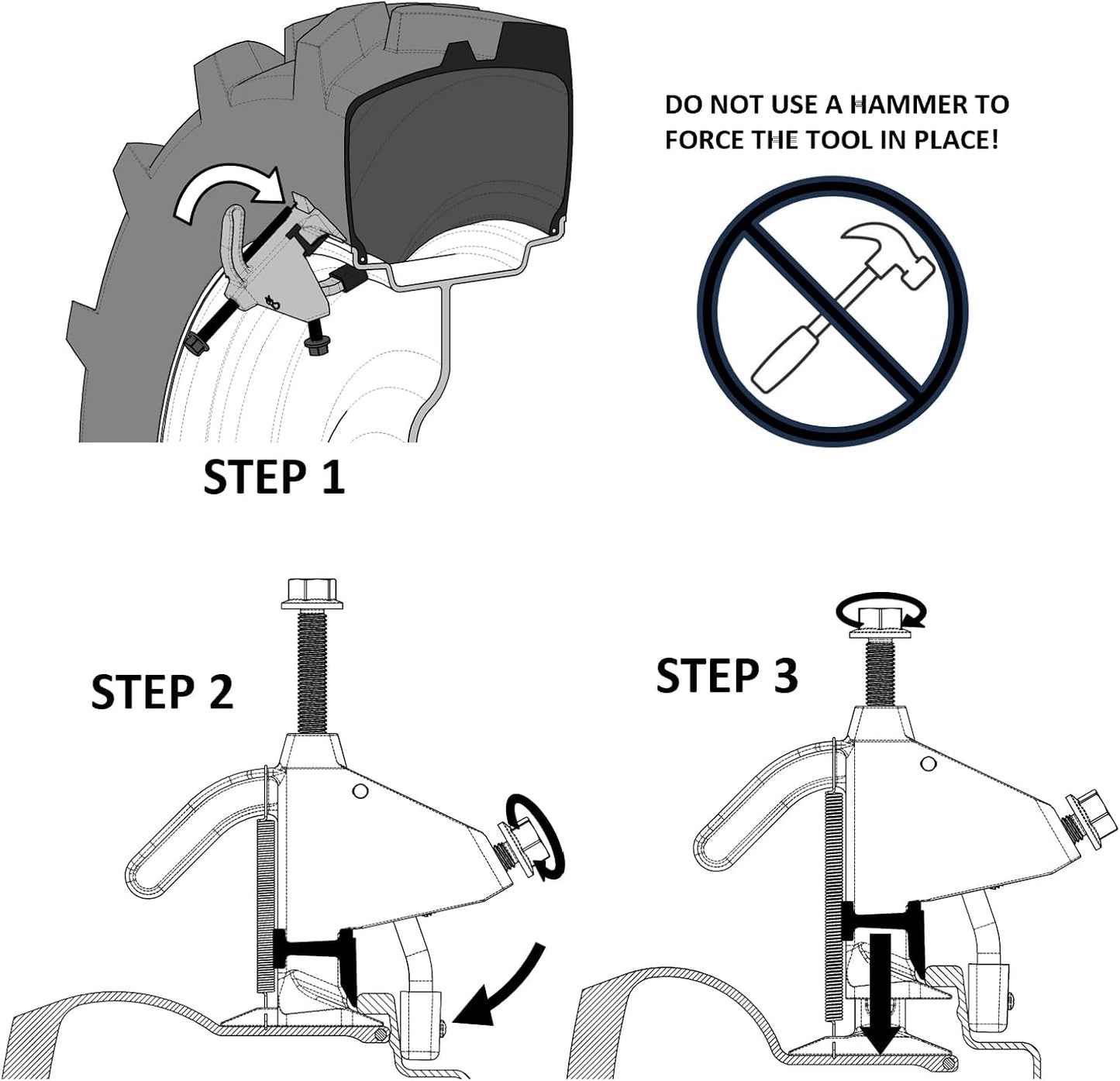

- Manually operated, use with a impact wrench or ratchet.

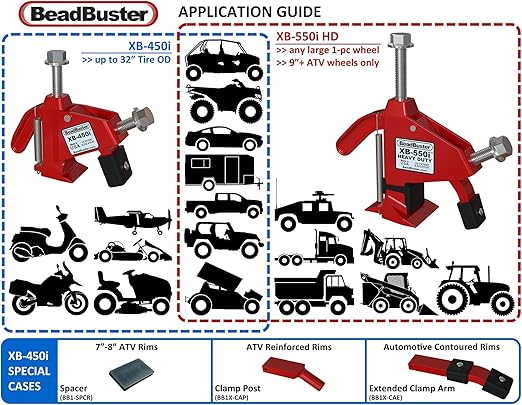

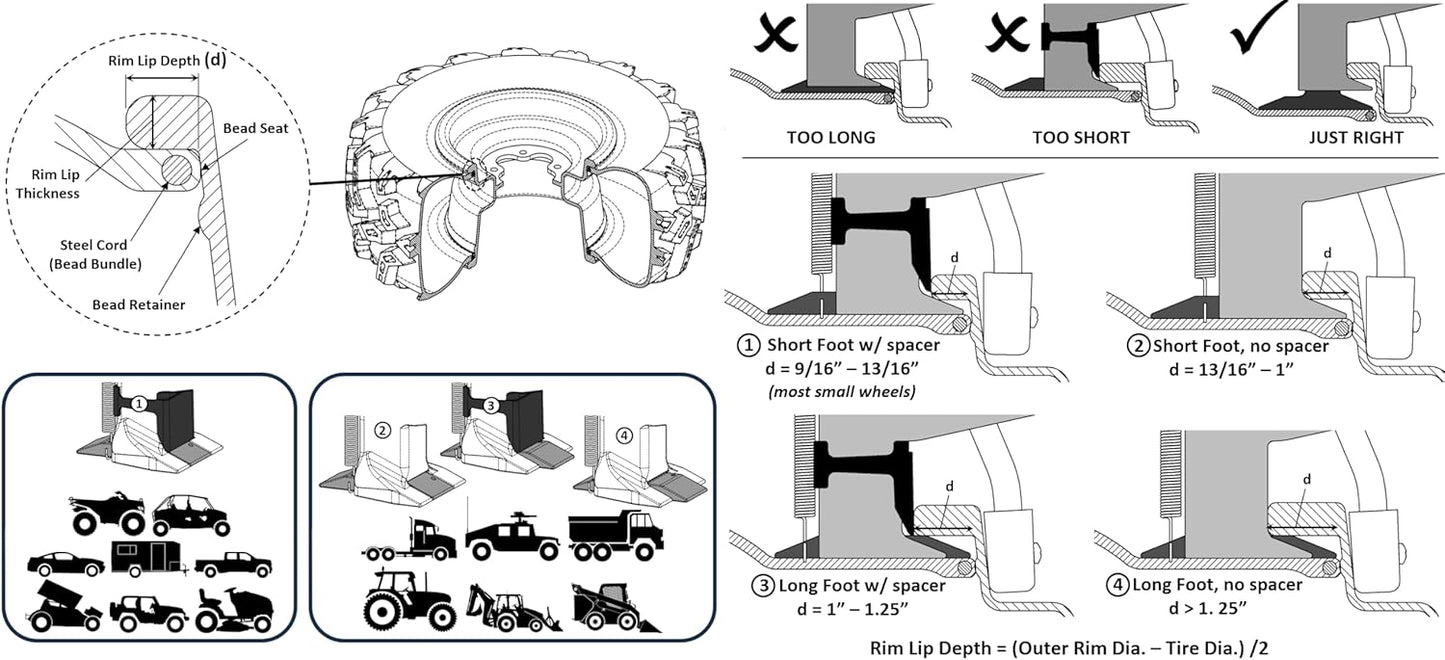

- Heavy Duty, works on any LARGE 1-pc wheel (Farm Tractors, OTR, etc).

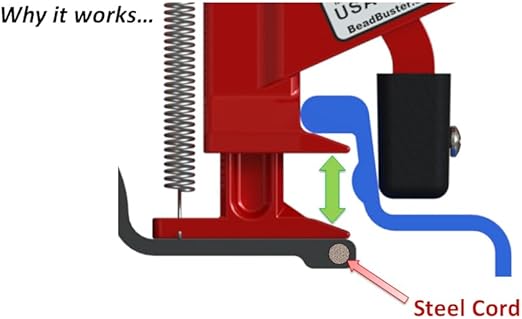

- Patented design quickly and easily breaks stubborn beads.

- Rugged single piece investment casting, made from hardened 4140 chrome-moly steel, Custom Grade-8 Zinc coated hardware.

- Padded clamp will not dent or scratch rims.

Product description